Competent partner for laser cladding

Shulert + Partner is your competent service provider for mobile laser welding with pulsed lasers under a microscope (Nd:YAG solid-state laser) and is available both at your site and in our own workplaces for Europe-wide jobs with our own mobile lasers.

Welcome to Shulert + Partners

We deliver guaranteed high-quality work results

Laser welding devices have long been the standard when it comes to precision, high demands and welded joints that have to withstand the highest loads.

Shulert + Partner, managed by Evgeny Shulert, is based in the small town Harsewinkel in the North Rhine-Westphalian district of Gütersloh in Ostwestfalen-Lippe, about 30 km west of Bielefeld.

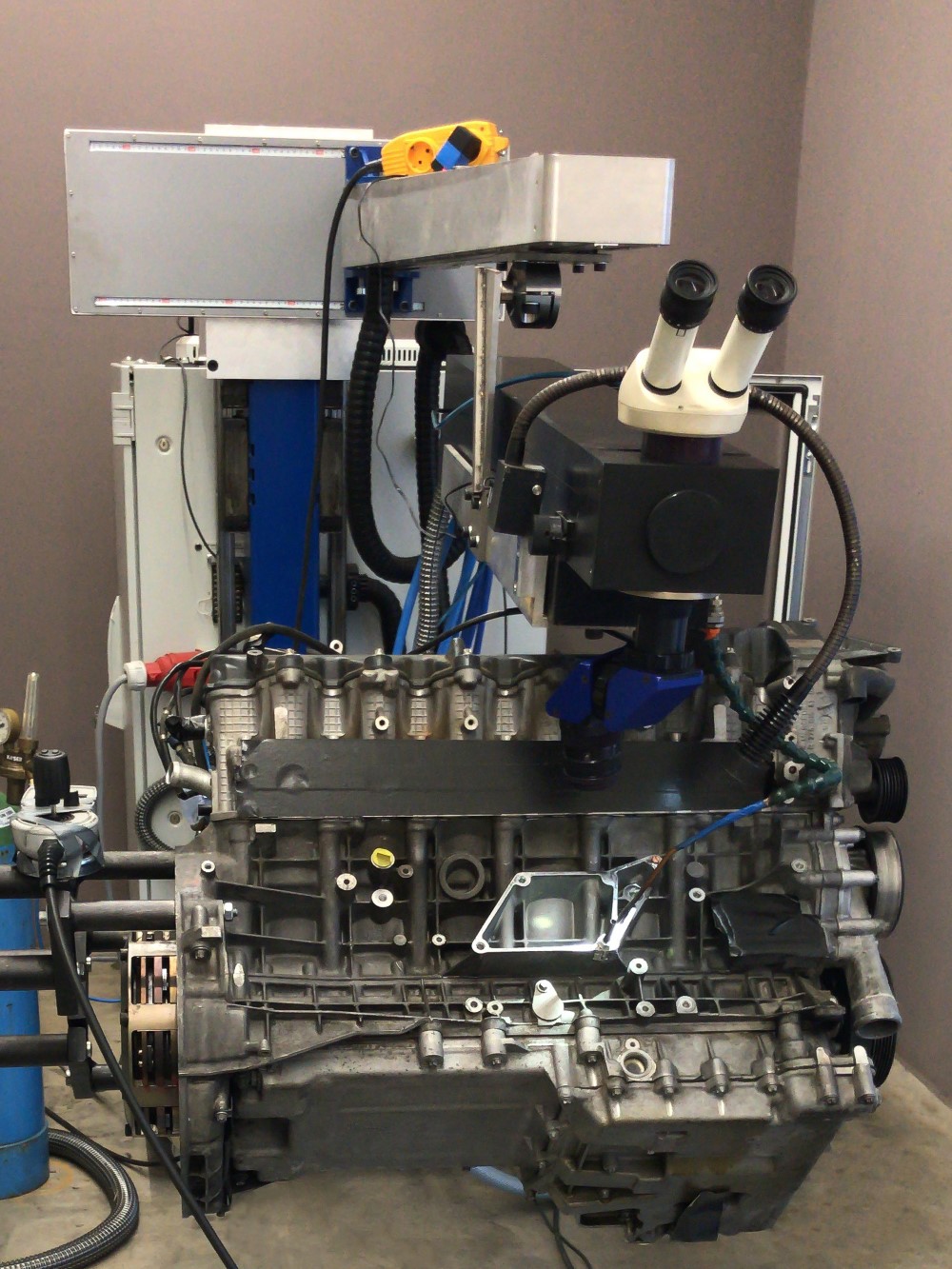

Since 2005, Shulert + Partners has specialized in pulsed, lamp-pumped Nd:YAG lasers with the main area of application being repairs and modifications (e.g. injection molding tools, special parts, light metal engine cast blocks), since the lamp-pumped system is proven to be particularly reliable when processing highly reflective materials such as aluminum, etc. has been proven.

As an additional and perfect surface finish, Shulert + Partners offers polishing services.

What to expect from Shulert + Partners

- professional, accurate performance

- 100% Satisfaction Guarantee

- individual customer solutions

- at your place (Europe-wide)

- at our own workplaces

- incl. return shipping up to 1 ton

Competence + Experience

Our services

Focused performance segment for the best ROI thanks to Know-How

The narrowly focused range of services enables the delivery of high-quality and professional work results.

- Laser Cladding

- Surface Finish

Laser Cladding

Laser cladding is suitable, for example, for various repairs such as building up, changing, expanding or joining. In addition, it is used to repair grinding marks on sliding surfaces. Filling of pores and cracks, dimension allowances for inserts and relining as well as repairing edges and points.

Surface Finishing

A perfect surface finish requires special know-how and sophisticated polishing technology. Shulert + Partners offers you both. We realize the solutions for you around your tools in the mold areas: die cast, injection molding, press molding and Forming tools reliable and guaranteed in 1A quality. Complete solutions including all repair work.

On-Site-Service

Do you have no way of delivering your order to our premises using the regular transport or would you like experts for laser cladding directly on site? Then our on-site service is just right for you. Simply send us the initial information regarding your order using the form here.

We look forward to your order!

Feel free to ask directly about your desired service in the required area of application without obligation and you will receive a fair offer with all the details.

exact. spot on.

Laser Cladding

Areas of application for laser cladding

- Injection molding tools

- Die casting tools

- Forming tools

- Jewellery (manufacturing, industry)

- Mould making

- Automotive

- Mechanical engineering

- Medical engineering

- Aviation

- Electrical engineering

- Automotive and Motorsports

- Science of measuring & control engineering

- Repair of polished surfaces

- Model change and modification

- Construction of 3D contours

What is laser cladding?

The welding technique and its application

Laser welding is the use of high-energy, coherent light on a narrow, precisely defined area which, in comparison to almost all conventional processes, produces almost no penetration, discolouration or structural changes (grain structure, coarse grain, embrittlement) under inert gas.

At high energy input a continuous welding seam is feasible, e.g. for car body sheet welding (automated).

With reduced energy input, the pulsed laser (often used as a mobile device) makes it possible to set individual welding spots or, at a low pulse frequency (typically 0 – 20 Hz), to make critical corrections, e.g. in mould making (also in graining).

For different kinds of materials, such as almost all Fe, Al, Cu alloys as well as Mg or Ti, filler materials are offered as wire (typically from 0.2 mm and upwards). upwards). Different degrees of hardness are available, so that even flat hard applications are possible. Good crack resistance can be achieved through careful selection of additives and welding parameters (e.g. pulse width).

Narrow gaps are required for welding without additional material (small laser spot).

The distortion problems that are characteristic of almost all welding processes are largely eliminated, as the energy input is only high at certain points. Preheating of the workpieces is not necessary (with exceptions e.g. for high degrees of hardness, to avoid crack formation).

Flexibility

Our manual and mobile welding systems (500 watts) enable a high level of flexibility with regard to the welding tasks, also directly at your site. An extensive range of laser accessories and additional materials is available for this purpose.

Efficiency

A 500 watt (mobile) and 800 watt (stationary) strong Nd:YAG pulsed laser allows working at high speed with a (0.2-1.2mm) welding wire diameter. We process small and large workpieces, tools and molds - regardless of contour, alloy and position.

Optical quality polishing results

Surface Finishing

A perfect surface finish requires special know-how and sophisticated polishing technology. Shulert + Partners offers you both.

We implement the solutions for you around your tools in the form areas:

- Die casting

- Injection molding

- Press molds

- Forming tools

reliable and guaranteed in 1A quality. Complete solutions including repair work. First-class processing technology in optical quality in 2-3 shift operation. We polish large tools in mold making (e.g. bumpers) on site.

We rely on partnership that is characterized by quality, flexibility and service.

Companies in the automotive supply industry and lighting technology trust us.

Polishing Services

- Mold polishes

- Contour polishes

- New polishes

Surfaces

- eroded

- milled

- sanded

Surface Quality

- Ra- 0,002µm

- Rz- 0,015µm

- Rmax- 0,025µm

References

Laser cladding (welding)

We would be happy to laser weld sample parts or a small series for you.

By using chemically inert or inert gases such as nitrogen or argon 5.0 (e.g. with titanium-containing steels), we can guarantee optically very attractive soot- and oxide-free seams of the best quality with laser welding.

Would you like to weld workpieces or components, but don’t know exactly how?

We are happy to advise and assist you!

Thanks to our many years of practical experience in laser welding, we are at your site to find solutions. After a detailed analysis, we will select a suitable procedure with you and coordinate the schedule realistically so that you can also count yourself among our satisfied customers after successful completion.

Below we have compiled some reference work both on site at some of our customers and directly from our production sites.

Contact Shulert + Partners

Request a Quote

Would you like to have a non-binding offer conveniently online? Then fill out the contact form completely and submit it.

You will receive the offer accordingly by e-mail.